China Wholesale Bucket Elevator Buckets Factories - Hot sale Vibrating Conveyors Electro Magnetic Vibratory Feeder Feed machine/automatic feeding throughout – Xingyong

China Wholesale Bucket Elevator Buckets Factories - Hot sale Vibrating Conveyors Electro Magnetic Vibratory Feeder Feed machine/automatic feeding throughout – Xingyong Detail:

Performance Advantages

1. The chain plate is made of food-grade polypropylene material mold, which has the characteristics of beautiful appearance, not easy to deform, high temperature and low temperature resistance, acid and alkali corrosion resistance, durability, operation, transportation, and large transportation volume. The baffle is an integral structure to transport materials without jamming, and is suitable for a wide range of materials.

2. The machine can complete the conveying work continuously or intermittently independently, or it can be matched with other equipment for conveying or feeding.

3. It can work independently or in series with other supporting equipment, which is convenient and simple.The nail chain feeder is easy to disassemble and assemble, and it is easy to operate, repair and maintain. All the work can be done without an expert. The chain plate can be quickly disassembled to remove residues, convenient for cleaning, and ensure food safety and hygiene in the food industry.

Optional configuration

1. Machine material: 304SS, carbon steel.

2. Contacting material: SS 304#, Belt material: PU, PVC or PR POM, PE(The latter two materials are not food grade, they are substituted by the food industry).

3. Standard Chain plate: total width: 400mm, effective width: 320mm, partition height: 75mm, distance: 254mm. Datas can be selected according to the material and qty.

4. Accept customized according to customer’s drawings.

Mechanical Usage

Vibratory Feeder Series:

Chain plate feeder

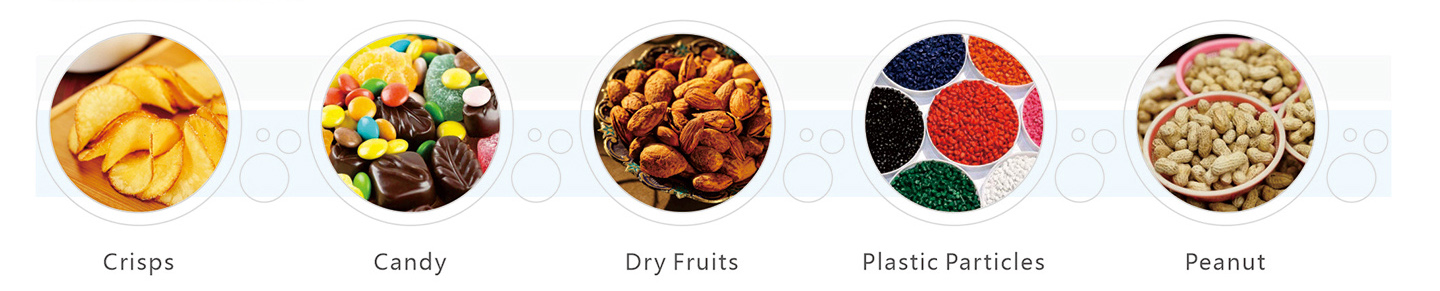

Biological segmented retaining material is added in the middle of the chain plate, and stainless steel or PP material can be added on both sides as fixed or movable retaining edges. The chain plate rotating feeding rib does not work with the chain plate rotation. Mainly suitable for conveying materials, with outer packaging, small bags of items, bulky bulk, block, packed carton. Such as candies, sausages, fruits, vegetables, chemicals, medicines, cartons, etc. The material can be transported horizontally or turned to the side. It can also be transported to the desired position by tilting or climbing. The chain plate material is pp, pom, pe and a variety of materials for customers to choose, and the chain plate has a beautiful appearance

Increase Stock Bin Independent Vibratory Feeder

An electromagnetically driven vibrating feeder is used to temporarily store material. The product uses the principle of electromagnetic elastic force to drive the power to push the material vibration to the conveying equipment to realize automatic feeding throughout.

Independent vibratory feeder 165L

Electromagnetic elastic driven to temporarily store, push & vibrate the material to the conveying equipment to realize automatic feeding.

Nail chain feeder

The middle of the chain plate is full of nail retaining materials, and the two sides are made of stainless steel or PP for fixed or movable sidewalls. The chain plate rotating feeding rib does not work with the chain plate rotation. Mainly suitable for conveying materials, vegetable products with roots and pasta. For example, bean sprouts, various noodles, snail noodles, etc., the materials are transported in parallel to the desired location.

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products and solutions into the market each year for China Wholesale Bucket Elevator Buckets Factories - Hot sale Vibrating Conveyors Electro Magnetic Vibratory Feeder Feed machine/automatic feeding throughout – Xingyong , The product will supply to all over the world, such as: Mombasa, Azerbaijan, Iraq, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.