CE Certification Zz Index Conveyor Manufacturers - Inclined bucket elevator,Food application module conveyor,Food industry conveyor/integral rotating feeding – Xingyong

CE Certification Zz Index Conveyor Manufacturers - Inclined bucket elevator,Food application module conveyor,Food industry conveyor/integral rotating feeding – Xingyong Detail:

Performance Advantages

Machine material: 304SS, carbon steel; net chain material 304 food grade stainless steel material.

Accept customized according to customer’s drawings.

Body material: 304 stainless steel, carbon steel.;Belt material: SS 304#, Belt material: PU, PVC or PR POM, PE.

Accept customized according to customer’s drawings.

Mainly suitable for conveying materials, vegetable products with roots and pasta. For example, bean sprouts, various noodles, snail noodles, etc., the materials are transported obliquely from low to the desired location.

Optional configuration

1. Skirt chain It is made of food grade polypropylene material mould, with beautiful appearance, not easy to deform, high temperature and low temperature resistance, acid and alkali corrosion resistance, durability, stable operation, large conveying capacity and so on. The baffle is an integral structure for conveying materials without jamming, which is suitable for a wide range of materials.

2. The machine can complete the conveying work continuously or intermittently independently, or it can be matched with other equipment for conveying or feeding.

3. Independent control box with reserved external porortt, also can be in series with other supping equipment. The delivery volume can be adjusted at any time according to demand.

4. Inclined bucket elevator Easy to be assembled, dismantled, cleaned and maintain. No professional is required. Belt is easy to be dismantled to clean the residue, to ensure food safety & hygiene in the food industry.

Mechanical Usage

Inclined bucket elevator Series:

Skirt baffle belt inclined bucket conveyor

The skirt belt is added from the belt to the skirt with two-way, Tightly squeeze and form the whole skirt skin with super glue and mechanical mold. Integral rotary feeding and conveying, It is mainly suitable for conveying powdery items in the material. Small bags of goods, chemical supplies. Powdered flour, various powdered items, fried materials or powdery materials on the outer surface, etc., transport the materials from a low place to the desired position.

Skirt baffle chain board inclined bucket elevator

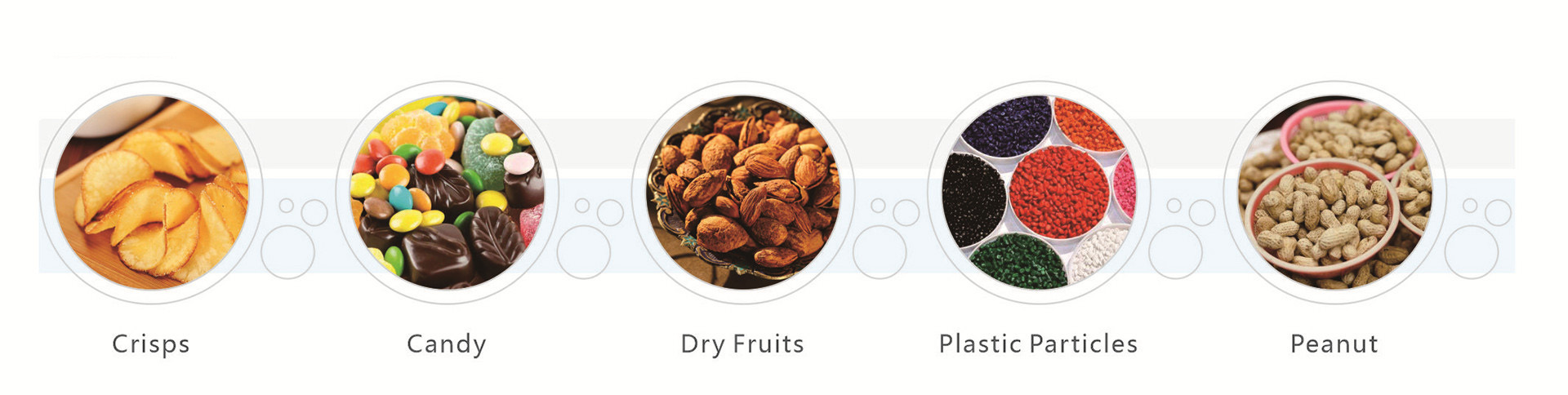

The skirt is a baffle skirt composed of multiple blades. Add an integrated segmented stopper in the middle to work. Integral rotary feeding. Mainly suitable for conveying materials, crops, small bags, chemical supplies. Size potato chips, peanuts, candies, dried fruits, frozen foods, vegetables, chemicals, medicines and other granular or block shapes, substitute products, and transport materials from a low place to the desired position.

Stainless steel mesh chain inclined bucket elevator

Both sides are made of 304 SS for fixed or movable ribs. The net chain rotates and feeds, and the ribs do not work with the rotation of the net chain. It is mainly suitable for conveying materials with water, oily materials, and alkaline materials that are easily corroded. Fried food, etc. The material is transported obliquely from a low place to the desired location.

Nail chain board inclined bucket elevator

The middle of the chain plate is full of nail blocking materials, and the both sides are made of stainless steel or PP for fixed or movable sides. The chain plate rotating feeding rib does not work with the chain plate rotation.

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for CE Certification Zz Index Conveyor Manufacturers - Inclined bucket elevator,Food application module conveyor,Food industry conveyor/integral rotating feeding – Xingyong , The product will supply to all over the world, such as: Italy, Liverpool, Yemen, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!