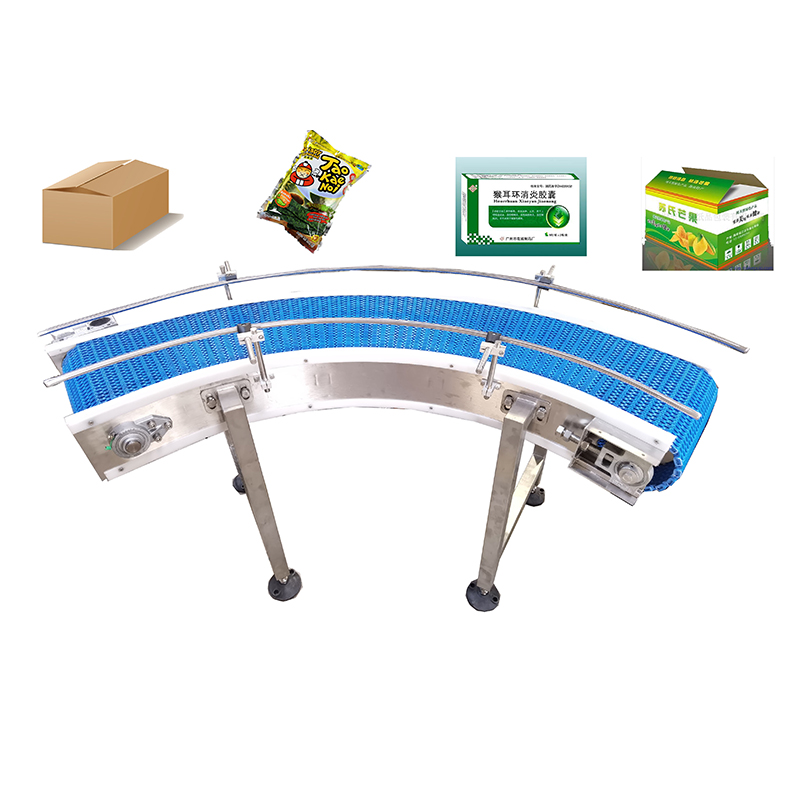

CE Certification Tooth Link-Belt Conveyor Manufacturers - Screw conveyor, Xiaolong elevator, powder feeding machine – Xingyong

CE Certification Tooth Link-Belt Conveyor Manufacturers - Screw conveyor, Xiaolong elevator, powder feeding machine – Xingyong Detail:

Screw conveyor

Automatic feeding of material eve tracking. lt can lso be used other occasions xcept for motor and bearing, the rest are made.

Product use: suitable for conveying non-stick dry powder materials and small amount of mixed wet materials and small granular materials, such as: rice, milk powder salt, soy flour etc. Application: suitable for conveying cohesionless dry powder materials, small amount of wet mixed materials and small particles of materials, such as rice, milk powder salt, soybean powder, etc. Product performance and.

Product Characteristic

1. The feeding machine adopts the main motor feeding for power rotation and rotary vibration motor as the feeding supplementary power, which can be separated separately and can be controled separately, and the external control can be unified.

2. With independent control operation E-box, reserve external control port can work independently or in series with othel supporting equipment, convenient and simple. The delivery volume can be adjusted at any time according to the requirements. The material is not easy to bridge and has strong adaptability to materials;

3. The silo and the conveying pipe are designed to be separated, the structure is reasonable, the loading and unloading is easy, and the transportation is convenient.

4. Unique multi-sealed and dustproof design keeps the bearing away from powder from dust and abrasion.

5. Designed to facilitate the cleaning of residual materials: the spiral can reverse the discharge, the lower end of the material tube has the gate discharge, and the whole spiral can be disassembled, cleaned, installed and maintained in a few simple steps.

6. According to the use environment, material characteristics provide a variety of ways for customers to choose.

Mechanical Usage:

Parameters

| Machine name | Screw conveyor | |||||

| Model | XY- LG15 | |||||

| Production capacity | 3 m³ /H 5 m³ /H 7 m³ /H 12 m³ /H | |||||

| Pipe Dia. | ø114mm ø141mm ø159mm ø219mm | |||||

| Power supply | 0.81KW 1.56KW 1.56KW 2.2KW | |||||

| Machine structure |

#304 Stainless steel |

|||||

| Hopper volume |

200-300L |

|||||

| Voltage |

Single-phase, two-phase or three-phase 180-220V, three-phase 350V-450V,50-90Hz |

|||||

| Angle of incline |

45degreefor standard,it can customeried for 30 or 60 degrees. |

|||||

| Discharge height |

2200mm standard, others available |

|||||

| Hopper type | ||||||

| Package size | ||||||

| Machine weight | 130KG / 180KG / 230KG / 270KG | |||||

Viedo

Product detail pictures:

Related Product Guide:

Our advantages are lower prices,dynamic sales team,specialized QC,strong factories,high quality products and services for CE Certification Tooth Link-Belt Conveyor Manufacturers - Screw conveyor, Xiaolong elevator, powder feeding machine – Xingyong , The product will supply to all over the world, such as: Tajikistan, Peru, Sydney, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.